Are you facing line efficiency issues?

There can be many reasons why your production line is not running at its most optimal efficiency. However, the most common problems can be solved by (dynamic) accumulation. The 5 major issues and how an accumulator can help are explained below.

What is conveyor accumulation?

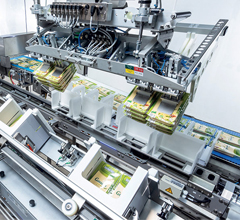

Accumulation is a process in which products are gathered before being passed on in the production line. This is done in order to make the most use of the machines involved. For example, if the input of a production line exceeds its output, an accumulation buffer can be used to even out these peaks.